How can Ignition MES truly improve your OEE and reduce downtime?

In the manufacturing industry, it’s all about efficiency. Machines must keep running smoothly, downtime costs money, and waste is unacceptable. OEE, or Overall Equipment Effectiveness, helps manufacturers see exactly how their production processes are performing. It combines three crucial factors: availability (how long machines actually run), performance (how well capacity is utilized), and quality (the proportion of well-produced products). By combining these figures, managers quickly know where processes are running well and where improvement is needed.

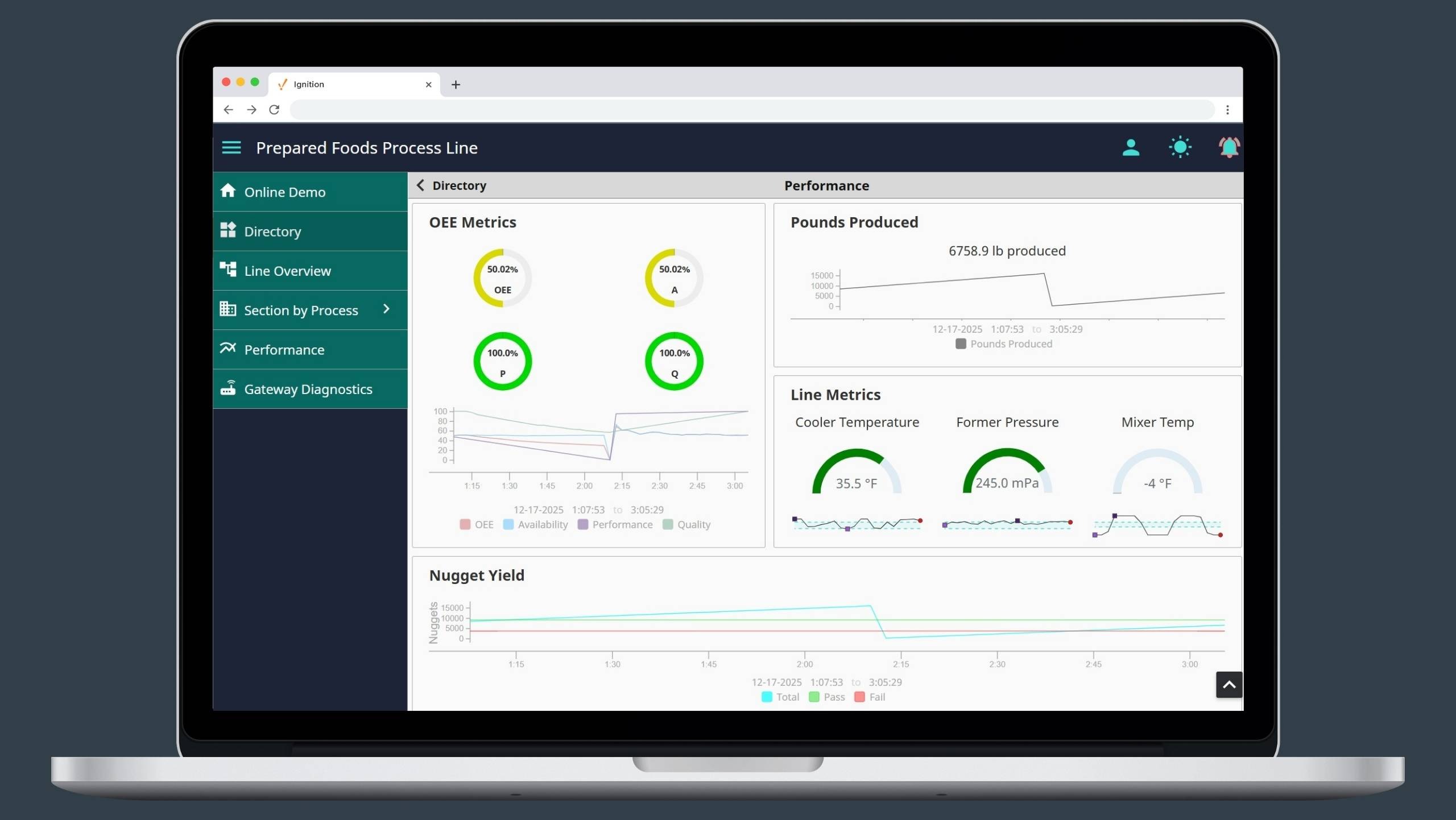

Ignition MES from Inductive Automation offers a practical way to make OEE transparent. The platform collects real-time data from machines, PLCs, and sensors and processes it into clear dashboards. Managers not only see what is happening, but can also intervene directly when deviations occur. Ignition is not just an MES package, but a future-proof data platform that finally gives companies complete control over their production.

EKK Eagle Simrax, a Dutch producer of seals for the automotive sector, modernized its production IT by replacing an outdated SCADA system and separate Excel reports with Ignition, implemented by AT-Automation. This provided one uniform data layer for production, maintenance, and management. Through realtime insight and automated reports, manual processes were eliminated, and teams gained direct insight into process performance – exactly what we mean by Master your growth. View the entire EKK Eagle Simrax customer case.

Advanced downtime registration with Ignition MES to reduce downtime

Unplanned production interruptions are one of the biggest expenses in the industry. Even short downtimes can lead to loss of quality, inefficient planning, and higher operational costs. That’s why advanced downtime registration is essential.

Ignition offers several tools to make downtime transparent and manage it efficiently:

Automatic data logging: downtime is registered in real time, based on machine signals or input from the operator.

Customizable dashboards: trends, patterns, and bottlenecks are immediately visible to plant managers and operators.

Event categorization: distinguish between different types of failures, material shortages, or operator errors.

Alerts and notifications: in the event of critical deviations, those responsible receive notifications via, for example, e-mail or SMS, so that they can intervene quickly.

These features create a complete, reliable picture of availability. This enables proactive maintenance and prevents companies from remaining dependent on gut feeling or manual registration. The result: less unplanned downtime, lower operational costs, and a more reliable production process. In addition, Ignition makes it possible to analyze historical data and tackle structural causes of failures. This shifts the company from a reactive to a proactive maintenance strategy – an important step towards a Next Level production process.

Case study: how LDPE Recycling improves OEE and operational efficiencyt with Ignition MES

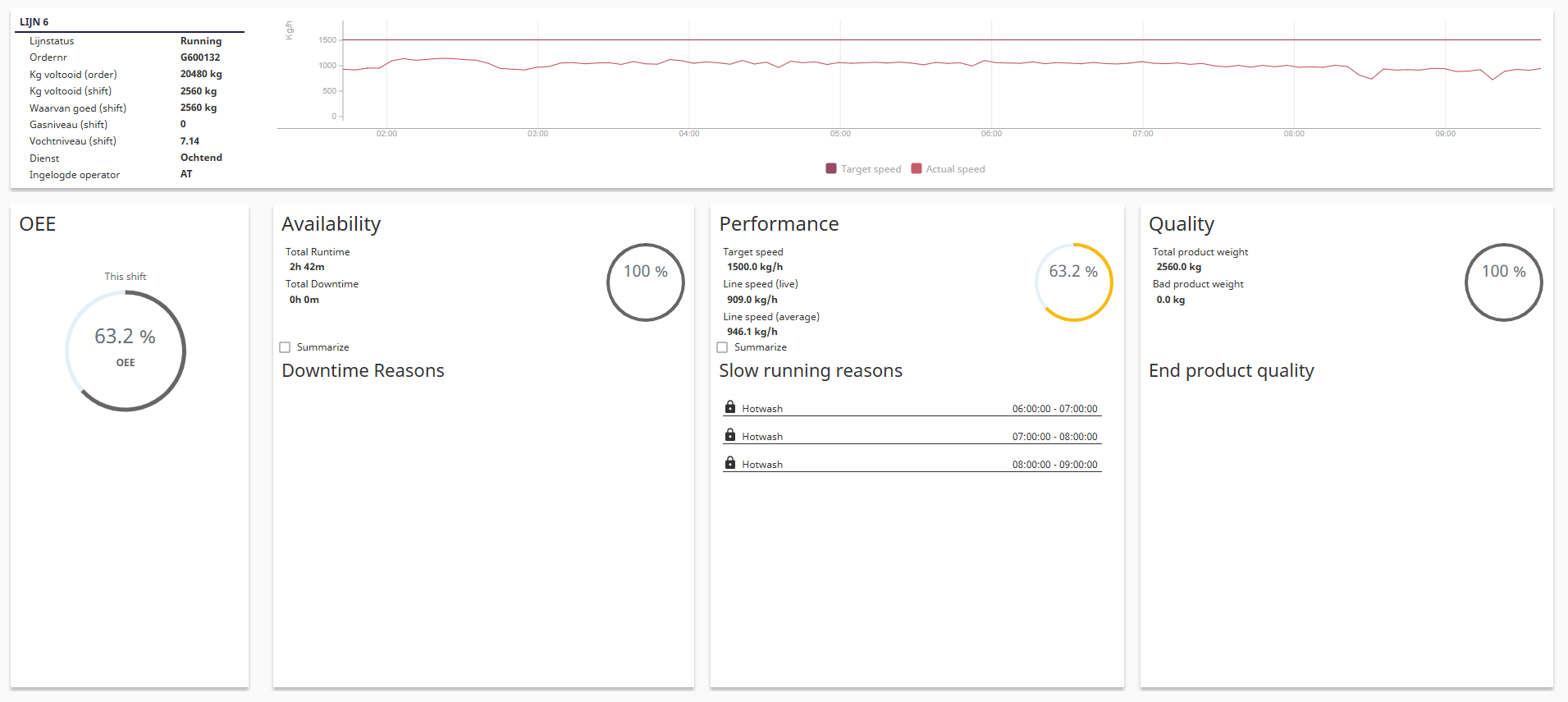

The power of Ignition MES is clear from practice. An AT-Automation project shows how real-time insight into downtime and performance makes OEE a practical management tool.

LDPE Recycling: Here, an OEE module was implemented in Ignition that automatically registers when a production line is stopped, how long, and why. Performance and quality are also included, allowing operators and managers to analyze more quickly where losses occur. The result: less unplanned downtime, faster failure analyses, and a more predictable production process. The standardization of data and visualization also created more ownership on the work floor – an essential part of our Master your growth philosophy. View the customer case of LDPE.

This integration shows why Ignition is ideally suited for companies that want to grow data-driven: one truth, fewer errors, more insight.

Maximizing OEE with Ignition: Best practices and recommendations

Optimally utilizing Ignition MES requires a structured approach. A number of proven best practices:

Full logging of machine signals record all relevant machine signals, from temperature and pressures to settings, for complete insight. You can read even more in-depth information about OEE in this knowledge base article.

Analyze historical data: investigate patterns of recurring failures so that preventive measures can be taken.

Alarm management: configure notifications so that critical deviations are visible, without users being flooded with irrelevant warnings.

User-friendly dashboards: these are designed so that operators quickly gain insight into OEE performance and failures. Clear visualizations and logical structures ensure that information is immediately understandable.

In addition, customization in dashboards is crucial. Not every production environment is the same; a good dashboard provides relevant insights for operators, team leaders and management. By building modularly, we ensure that dashboards grow with the needs of the company – scalable, applicable and future-proof.

More insight. Less Production Loss. Higher OEE.

That is the power of Ignition – and of AT-Automation as Premier Ignition Integrator. Curious? Schedule a demo or free consultation below and discover your growth potential.

Stay up to date

Receive our monthly newsletter in your inbox.

Or follow us

Wat is een goede OEE-score?

Waarom is mijn OEE laag en hoe kan ik die verbeteren?

Hoe wordt OEE berekend en wat betekent het?

Ready to Master

your growth?

Discover how Ignition MES can improve your production. Fill in the form for a free consultation or demo!

Share this article

You might also like

Software Engineer at AT-Automation: John on growth and international projects in Weert

John Meerten (27), who started as a PLC engineer on the shop floor, took an unexpected turn to become a Software Engineer at AT-Automation. Read how he now connects clients’ office networks with the production floor and manages international projects.

AT-Automation B.V. acquires Van Daal Engineering

Weert, September 1, 2025 – AT-Automation B.V., a leading industrial automation company with two locations in Weert, announces the acquisition of Van Daal Engineering, effective September 1st, 2025. With this strategic acquisition, AT-Automation strengthens its...

What should you consider when choosing a SCADA/MES system?

A good SCADA/MES system plays a crucial role in this. It enables companies to collect production data, monitor processes, and intervene immediately in case of failures or deviations. However, not every system…