Digitalization in Manufacturing: Cloetta Case Study Powered By

AT-Automation

In het kort

Bij Cloetta hebben we, in samenwerking met AT-Automation, gekozen voor een digitale transformatie door het implementeren van een robuust platform met Ignition als basis. Het doel was om verouderde systemen te moderniseren en meer inzicht te krijgen in de productieprocessen.

In plaats van handmatig gegevens te verzamelen, maken we nu gebruik van een ‘data engine’ met een Unified Namespace (UNS) die data van de productielijnen centraliseert. Dit stelt ons in staat om in real-time weloverwogen beslissingen te nemen op basis van feiten. Met de toevoeging van de Sepasoft MES OEE-module hebben we snel een dashboard kunnen implementeren dat operators en management directe inzichten geeft.

De architectuur, gebouwd op een Linux-omgeving met Docker-containers, zorgt voor snelle uitrol, flexibiliteit en schaalbaarheid. Het resultaat is een efficiënte, datagedreven aanpak die ons in staat stelt om meer te doen met dezelfde middelen en de productie naar een hoger niveau te tillen.

About Cloetta

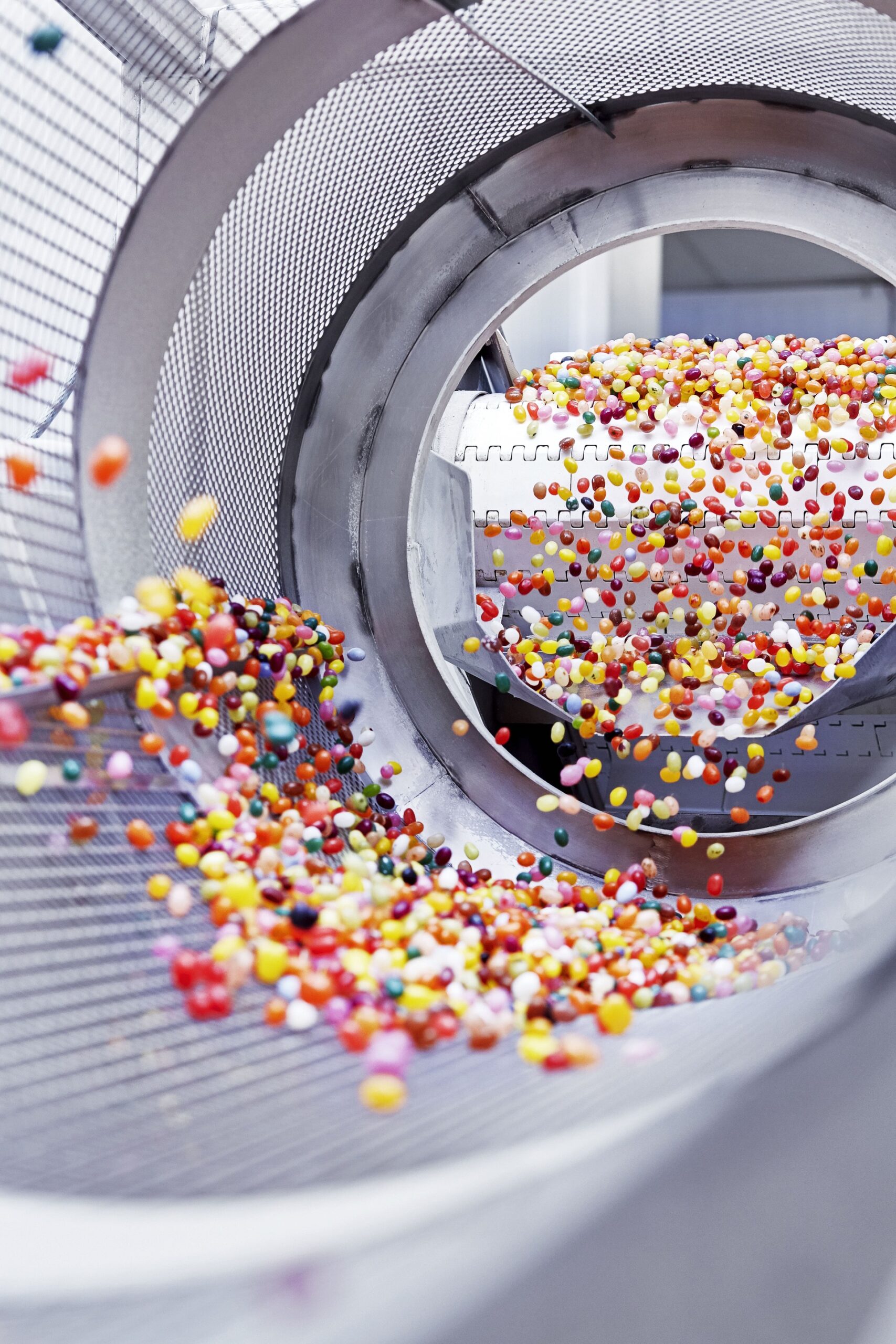

Cloetta is the leading confectionery company in Northern Europe, with the vision to be the winning confectionery company that inspires a happier world. Their core markets are Sweden, Finland, Denmark, Norway and the Netherlands and their products are sold in more than 60 countries worldwide. Cloetta has six production facilities in five countries and the company’s B-shares are traded on Nasdaq Stockholm.

The Challenge at Cloetta

Cloetta faced the challenge of modernizing their traditional, outdated OT systems. Many experts on the production floor spent time on administrative tasks, such as manually collecting data from various systems and machines. This data was then put into spreadsheets, which led to a reactive approach to problem-solving. By the time the cause of a problem was found, new problems had already arisen.

The machines were often disconnected from each other (‘siloed’), which made it almost impossible to get a complete overview. This resulted in a lack of data and time to implement the necessary improvements. The challenge was further increased by increasing competitive pressure, the difficulty of finding skilled labor, and the need to produce more with the same resources at lower costs.

The vision was to create a digital platform with a powerful ‘data engine’ as a crucial component. This platform had to connect all systems and employees with each other, so that fragmented data could be converted into real-time, fact-based decisions. The goal was to build a modular, scalable solution that could quickly deliver results with minimal risk, in order to make the transition to Industry 4.0 and transform operations.

Jan van Hoef, LCS

Digitalization in Practice: from Challenge to Data-Driven Efficiency

At Cloetta, a fundamental shift has been initiated from a traditional to a proactive, data-driven approach. The digital transformation is focused on giving better technology to employees, rather than replacing them with machines. The implementation of a Unified Namespace (UNS) has centralized the previously fragmented data, making it possible to make fact-based decisions.

A crucial element in the success of this project is the chosen infrastructure: a Linux environment with Docker containers. This architecture makes it possible to quickly set up new development environments with minimal effort, providing more flexibility and reducing the risk of errors. By using Ignition as the central ‘data engine’ and the Cepasoft MES OE module, a dashboard could also be set up quickly, providing direct insight. Another remarkable achievement was the rapid integration with the ERP system via MQTT, something that normally takes much more time.

All of this has led to Cloetta now having a scalable and future-proof platform that forms the basis for further steps towards Industry 4.0.

Want even more inspiration? A similar transformation took place at LDPE Recycling, where Ignition and a central Historian replaced paper registrations and enable real-time insight into processes.

Gregory Grauwels, Cloetta

Ready to master your growth?

Are you ready to take your operational processes to the next level? Discover how an integrated system like Ignition can transform your business. Contact us today and let us help you optimize your production and improve your efficiency!