In Brief

At Sekisui Alveo, the European market leader in polyolefin foams, the challenge was to modernize outdated production systems and gain better insights into their data. To achieve this, AT-Automation was called in.

About Sekisui Alveo

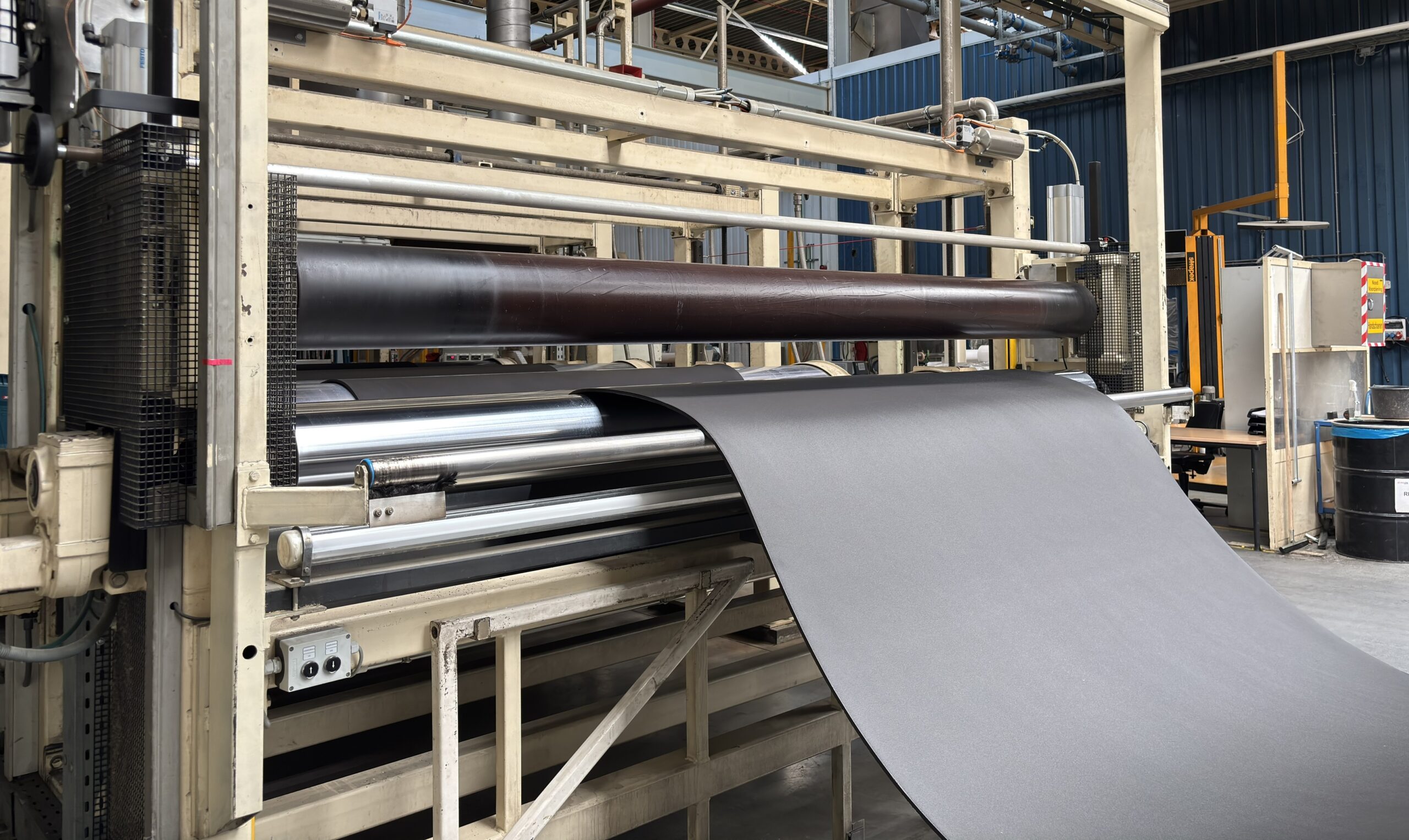

Sekisui Alveo is the European market leader in polyolefin foams, with production locations in Roermond, among others. They supply customized foam solutions for various sectors such as automotive, construction, medical applications, and packaging. As part of the global Sekisui Chemical Group since 1971, Sekisui Alveo combines innovation with decades of experience and a strong focus on quality and commitment.

The Challenge at Sekisui Alveo

Sekisui Alveo was looking for a way to make production data more transparent: clear trend lines, live data, clear visualizations of process values, and uniform reports. They also struggled with outdated control technology, including machines with S5 PLCs that were in urgent need of modernization. The company wanted a partner that could not only supply software but also offer mechanical adjustments and a total package of engineering and execution.

Through a former colleague familiar with the Ignition platform and AT-Automation, Sekisui Alveo came into contact with AT-Automation. The combination of broad technical knowledge, market-conform pricing, and the ability to handle the entire process from engineering to execution made the choice easy. They have now been working together successfully for a year and a half and several conversions and software projects have been carried out.

Jan van Hoef, LCS

AT-Automation Offered a Combined Approach

Modernization of the control technology

Old S5 and S7-300 PLCs have been replaced by modern Siemens S7-1500 series PLCs, making the hardware standardized and future-proof. New control cabinets set up according to NEN 60204-1 (machine safety). The existing color coding has been retained so that technicians and operators remain immediately familiar with the diagrams.

Consistent design of control cabinets

New control cabinets are uniformly equipped with standardized components and colors, in accordance with the NEN 60204-1 standard for machine safety, and with retention of existing color codes for recognizability.

Simpler maintenance and better knowledge transfer

Components have a lifespan of approximately 20 years or a certain number of circuits, making preventive maintenance essential to guarantee the required PL or SIL levels. Simple replacement hardly improves the efficiency of the control line, but with re-engineering, the process can be significantly optimized, for example by adding HMIs or robots so that work processes can be reduced.

Data visualization and reporting with Ignition

- Customized real-time dashboards for operators, management, and directors

- Automatic reports and alarm notifications

- Improved control of processes and compliance with data logging requirements

- The Perspective module and the Tag Historian are used in Ignition. For important dashboards, trend lines from the Tag Historian are mainly displayed, making real-time data transparent. There is also a link to a database for storing the Tag Historian data.

“AT-Automation thinks in solutions, not in problems. They not only signal what is wrong, but immediately come up with clear options and associated pros and cons. That proactive attitude makes the difference.”

Peter Cranenbroek, Sekisui Alveo

Results Impact

- Peace of mind and uniformity: Four of the eight lines now have the same standardized control cabinets, which increases recognizability and ease of maintenance

- Better collaboration: One software platform (Ignition) for multiple departments, which promotes knowledge sharing and independence

- Higher reliability: Old components from the 90s replaced by modern technology, with less downtime and better support. The hardware upgrade allows preventive maintenance to be carried out better, the safety level remains guaranteed and the reliability of the line increases.

- Faster deviation detection: Deviations are detected earlier, standstill can be better prevented.

- Efficient data visualization: Custom-made dashboards for different roles ensure consistency and overview.

The implementation of Ignition continues, with the expansion of dashboards, automatic orders, notifications, and reports. Due to temporary capacity pressure, ongoing projects have been completed first. The collaboration is solution-oriented and proactive, with AT-Automation offering several options.

With the successful implementation of Ignition and the continuation of the improvement process, Sekisui Alveo is better prepared for the future, with more control, efficiency, and reliability in production

Ready to master your growth?

Are you ready to take your operational processes to the next level? Discover how an integrated system like Ignition can transform your business. Contact us today and let us help you optimize your production and improve your efficiency!