Unified Namespace for BMT Aerospace: Data central & structured

In Brief

At BMT Aerospace, we have implemented a Unified Namespace (UNS) using Ignition and IIoT technologies to transform fragmented industrial data into structured, real-time insights. This Unified Namespace makes it possible to centrally manage production data, better monitor processes, and make faster decisions. Thanks to the collaboration with AT-Automation, the implementation has been efficient and the system delivers measurable benefits for both operators and management.

Watch the video case study about how BMT Aerospace, together with AT-Automation, transformed their industrial data with a Unified Namespace, IIoT, and Ignition SCADA. This case study has won the ICC Discover Gallery Award.

Read more background information about IIoT in our article What is IIoT?

About BMT Aerospace

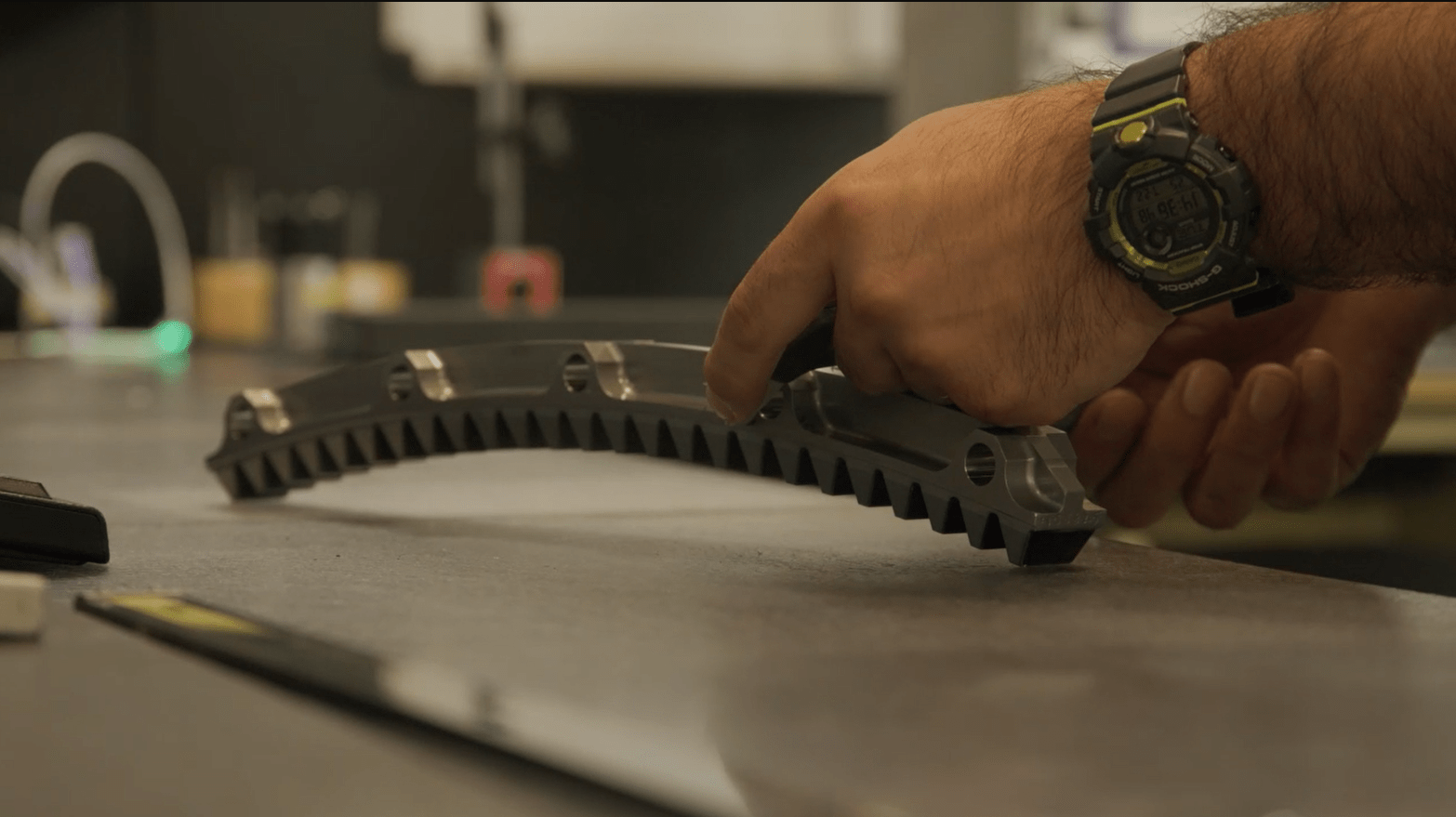

BMT Aerospace is a trusted supplier of gears and mechanical components for the global aerospace industry. The company specializes in five core areas: gears for movable wing components, gearboxes for turbine engines, shafts and couplings, high-precision detail gears, and bevel, spiral, and ring gears.

All products are developed according to the highest industry standards, with a clear focus on weight reduction and performance. BMT Aerospace is fully vertically integrated, combining advanced engineering, high-quality materials, precision machining, and special processes—such as heat and surface treatments—to deliver reliable and powerful solutions.

With production facilities in Belgium, the United States, and Romania, BMT Aerospace supports a broad spectrum of aerospace platforms and leading engine programs. Their components are used in commercial and military aircraft, regional and VIP jets, helicopters, and turbine engines from prominent OEMs and engine manufacturers. In addition, they also contribute to selected space programs.

The Challenge at BMT Aerospace

What began as a small-scale innovation initiative evolved into a company-wide digital transformation strategy at BMT Aerospace. The goal was to create a robust, scalable platform that collects machine and operator data, adds context, and makes it usable across the entire organization.

The company faced several challenges: more than 70 different brands of machines and equipment needed to be integrated into a single system, while production floor data was fragmented, limiting insights and decision-making. At the same time, an outdated MES had to be replaced and a new ERP system supported, without disrupting ongoing operations.

BMT Aerospace’s vision was clear: to create one central, user-friendly system that not only consolidates data from all production lines, but also contextualizes and makes it actionable for the entire organization, while at the same time providing a solid foundation for further steps toward Industry 4.0 and advanced data analytics.

Jan van Hoef, LCS

Central Single Source of Truth

To meet these challenges, AT-Automation developed an integrated solution based on the Ignition platform. The system acts as a shop floor controller and collects data from Beckhoff IPCs, PLCs and sensors, and integrates it into a Unified Namespace (UNS). The data is stored securely and in a structured manner, shared via MQTT, and made available historically in Canary Labs.

Operators and management have access to real-time and historical data via intuitive dashboards, making it easier to monitor processes, gain direct insight into performance, and quickly detect deviations. By centralizing systems and data, the platform reduces inefficiencies and increases productivity on the shop floor.

Thanks to this solution, BMT Aerospace can not only optimize current production processes, but a solid foundation has also been laid for future innovations, such as digital twins, process optimization with AI, and a fully autonomous, self-learning factory.

Want even more inspiration? A similar transformation took place at LDPE Recycling, where Ignition and a central Historian replaced paper registrations and enable real-time insight into processes.

Koenraad Lievens, BMT Aerospace

Ready to master your growth?

Are you ready to take your operational processes to the next level? Discover how an integrated system like Ignition can transform your business. Contact us today and let us help you optimize your production and improve your efficiency!