Control Engineering at AT-Automation: The vision of team leader Jack Vonken

When you think of industrial automation, you might picture large factories, complex systems, and impressive machines. Behind these systems, however, lies a world of smart technology and precise control. At AT-Automation in Weert, we help manufacturing companies in the Netherlands and Europe ensure their systems operate reliably, efficiently, and are future-proof.

As Jack Vonken, Control Technology Team Leader, says: ‘No two days are the same.’ Since September 2023, he has combined technical expertise with leadership. Jack oversees projects from estimation and quoting to execution and delivery, while giving his team the freedom to work independently: within the framework of a project, everyone is encouraged to apply their own insights to make a project a success, with the ultimate goal of a satisfied customer. We don’t check every detail, but provide trust and guidance where needed.

What AT-Automation does

AT-Automation helps companies with everything involved in automating and optimizing production processes.Jack explains: “From consulting, pre-engineering, and design to implementation and maintenance. This includes hardware engineering and panel construction, installation, and the software programming of the control systems. Our goal is for systems to operate reliably, safely, efficiently, and with future-proof performance. We manage the entire process, ensuring that the customer is fully relieved of worries while maintaining control over their production process.”

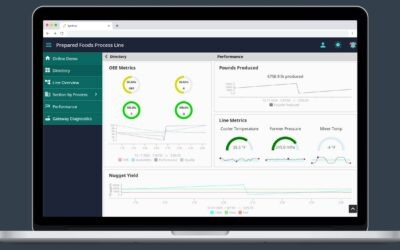

The company also designs and builds custom robotic cells and solutions, programs software using the Ignition platform, and provides comprehensive service and aftercare. Projects vary from modernizing existing systems to automating new production lines. Sometimes customers call us for an ad-hoc malfunction, other times we carry out an entire project from design to delivery. Every day brings new challenges,” says Jack.

Craftsmanship in control engineering: team in Weert

The Control Technology team stands out for both technical expertise and teamwork. Jack: “It’s not just about knowledge. You need to fit in with the team and have the right attitude. We’re looking for specialists who are quality-focused, practical, and analytical. Being able to work independently is important, but so is being willing to learn and collaborate.”

New employees can make an impact from day one. “Daring to share your opinion and make independent decisions is important. If someone notices something we hadn’t thought of yet, we appreciate it. It strengthens the entire team.”

At the same time, the team places great value on an informal atmosphere: ‘There’s always room for a joke. You don’t have to be tense all the time. But craftsmanship always comes first. Good is only good when the specialist is proud of it.

Control over production processes with modern control engineering

For AT-Automation, it’s all about control, knowledge, and oversight for customers. “We ensure production processes run reliably and that customers fully understand how their systems work,” says Jack. “We advise, design, program, and maintain, so teams can make informed decisions themselves and continuously improve processes.”

This approach delivers tangible results: less downtime, higher efficiency, and future-proof installations. AT-Automation helps customers gain deeper insight into their systems and supports them in independently managing their production environment. “We are a partner, not just a supplier,” emphasizes Jack.

Growing as an organization and as a professional

Recently, the Control Technology team was strengthened with seven new colleagues, including PLC engineers, hardware engineers, and technicians. Growth at AT-Automation isn’t just about customers-it’s also about employees: everyone has the opportunity to develop their knowledge, skills, and responsibilities. Thanks to the flat organizational structure, everyone’s opinion is heard from day one. “You can contribute ideas to porjects and the direction of the company,” says Jack. “This means direct responsibility and freedom, always supported by a close-knit team.”

Trends in industrial automation: the future

The world of control engineering is changing rapidly. “New products and technologies make the work exciting,” says Jack. “At the same time, knowledge in many factories is declining, and skilled personnel in technical maintenance are becoming increasingly scarce. That’s why we position ourselves as a partner for our clients, supporting them with advice and action. In this way, we contribute to continuity and ensure that automation becomes an increasingly important part of their future vision.

AT-Automation actively addresses this by optimizing systems and supporting maintenance, enabling clients to work independently and continuously improve their production.

Local presence and client relationships

Thanks to our local presence in Weert, the team can respond quickly to malfunctions and work closely with customers. Regular meetings, short lines of communication from the office, and on-site visits ensure direct and reliable collaboration. Jack emphasizes: “We are involved in the entire process and share our knowledge. Customers can count on us for solutions that truly work.”

Why clients choose AT-Automation

According to Jack, the difference lies mainly in our way of working: quality always comes first, with transparency and solutions delivered entirely in-house. From hardware and software to installation and maintenance – the team provides systems that grow with the customer’s business. “We focus on the long term: open, honest, and fully engaged in our customers’ production, with our own staff so they can rely on our expertise and service,” says Jack.

Master your growth

Our team’s commitment and expertise are reflected not only in the solutions we deliver to customers but also in how we collaborate within AT-Automation. Working with us means being part of a dynamic, technical, and growth-oriented environment. Jack concludes: “We are a close-knit team of passionate professionals who hold quality in the highest regard. Together, we continuously develop ourselves and our solutions to optimally support our customers. That makes both our work and our team truly special.”

Stay up to date

Receive our monthly newsletter in your inbox.

Or follow us

Share this article

You might also like

How can Ignition MES truly improve your OEE and reduce downtime?

Ignition MES from AT-Automation provides real-time insight into production, improves OEE, reduces downtime, and makes maintenance proactive.

Software Engineer at AT-Automation: John on growth and international projects in Weert

John Meerten (27), who started as a PLC engineer on the shop floor, took an unexpected turn to become a Software Engineer at AT-Automation. Read how he now connects clients’ office networks with the production floor and manages international projects.

AT-Automation B.V. acquires Van Daal Engineering

Weert, September 1, 2025 – AT-Automation B.V., a leading industrial automation company with two locations in Weert, announces the acquisition of Van Daal Engineering, effective September 1st, 2025. With this strategic acquisition, AT-Automation strengthens its...