From pen and paper to a hypermodern, data-driven factory

LDPE Recycling

LDPE Recycling is one of the largest players in the Netherlands when it comes to recycling LDPE film – the type of plastic used in carrier bags. What starts out as waste in consumers’ hands gets a second life at LDPE Recycling.

With growing awareness that recycling must become smarter, faster, and more sustainable, LDPE Recycling has made significant strides in digitalization and automation in recent years.

One of the driving forces behind this transformation is Rob Keunen, who has been with the company for nearly 19 years. He started on the shop floor as an operator and worked his way up through process and project management roles to his current position as Continuous Improvement Engineer.

The challenge

In 2020, a new site director took the helm with a clear mission: build a new factory with new production lines. Rob was given a key role in this project – the full digitalization of production. No small task. “I was handed the responsibility for automation, SCADA, software development, and data,” says Rob. “And honestly, I had no idea where to begin. In the recycling industry, digital approaches like this are far from standard. In the automotive industry – where our new director came from – SCADA and data-driven working have been the norm for years.”

Laying the groundwork

The search for the right software partner began at group level, but when that process stalled, Rob was given the freedom to look locally. Through his network, he came into contact with AT-Automation.

What followed was no rushed software selection. Quite the opposite. A thorough pre-study was carried out first. In multiple sessions, involving departments like Operations, Technical Services, Quality, and IT, the team mapped out what was truly needed – and just as importantly, what was not.

Rob Keunen, LDPE Recycling

The power of Ignition and a different approach

LDPE Recycling ultimately chose the Ignition platform, not only for its technical advantages – such as modular design and one-time license costs – but also because of the collaboration with the people at AT-Automation. “What I really appreciated was the direct communication. No layers or slow processes. I still speak directly with the software engineer via Teams, and that makes everything so much more efficient.”

The technical approach

Today, two new production lines are fully operational on the SCADA system. The system consists of several components:

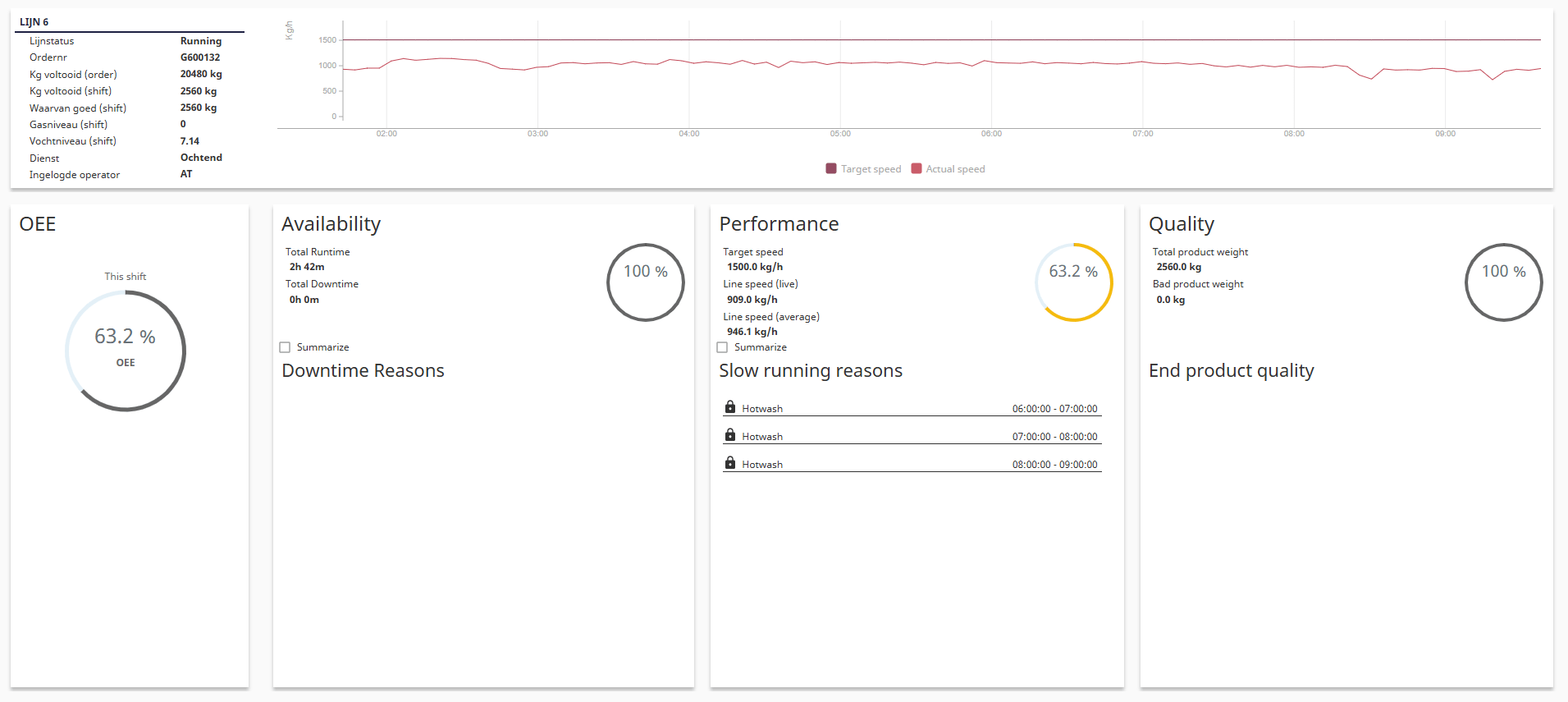

1. OEE module

The first and most important module implemented was the OEE module, which accurately measures how efficiently the lines are running:

- Availability: When is the line down? Why? And for how long?

- Performance: What is the output per hour, and how does it compare to the target?

- Quality: How much good product is being produced, and how much is rejected?

Rob explains: “Our extruders have built-in scales, which we connected to Ignition. If the output reads 0 kg, the system knows the line is down and prompts the operator to select a reason. This builds real-time downtime data. If the line is running but output is too low, the system asks why. This encourages active involvement and gives us reliable data.”

A quality check was later added using a smart sensor on a valve. If it switches from good to bad product, the system registers it automatically.

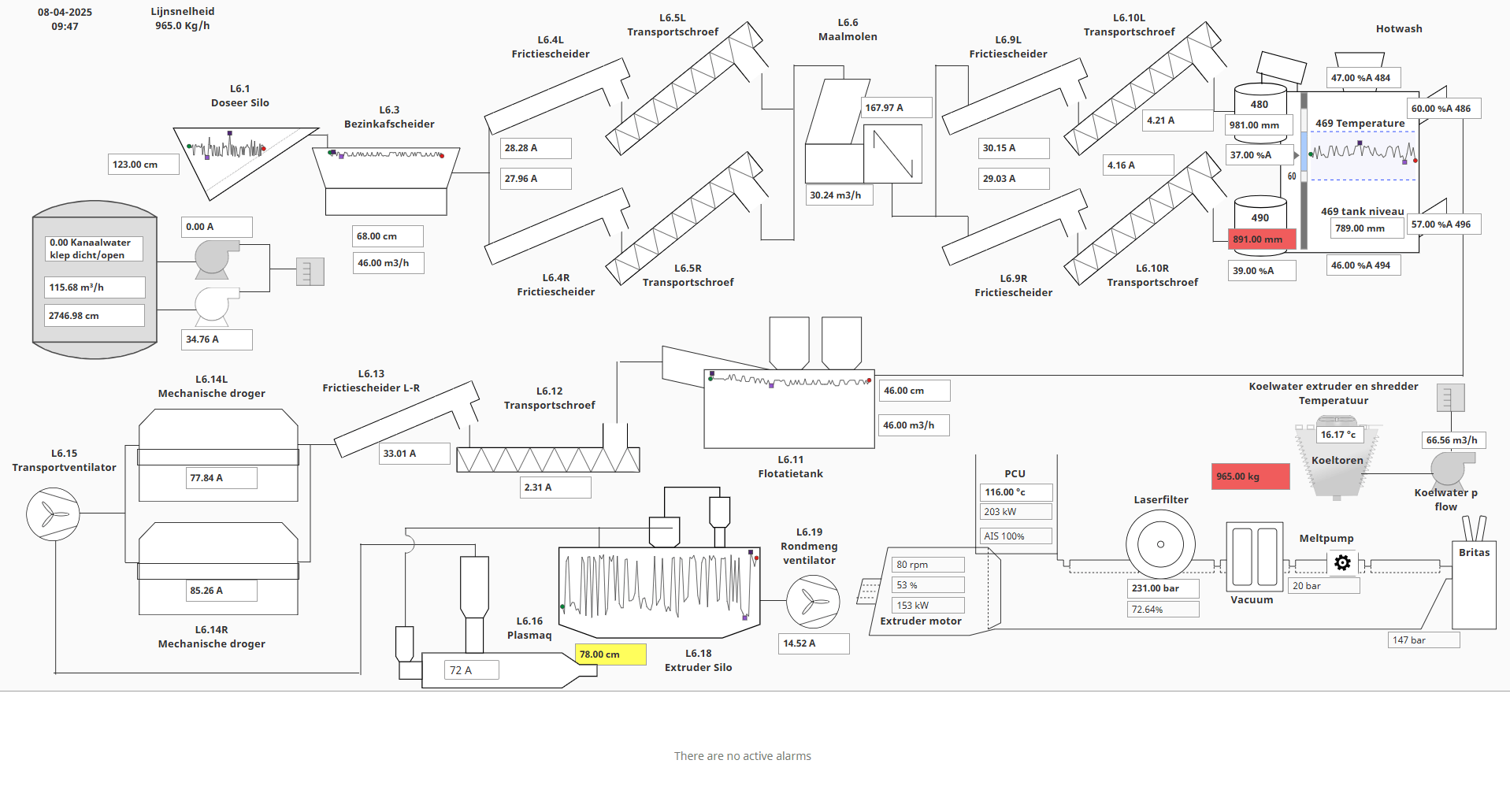

2. SCADA system

A completely new SCADA system was developed, mapping all machines on the line visually from start to finish. The user interface was designed according to the international ISA 101 standard – meaning muted colors, uniform symbols, and clear contrast.

“We came from an era where HMI screens were full of colors, icons, gauges, and bars. It looked impressive and worked fine at the time, but it wasn’t always intuitive. Now, the simplicity makes it powerful. If something turns red, you notice it immediately.”

Visibility was also key. LDPE Recycling intentionally placed large screens on the production floor and near office areas. “Those screens are worth their weight in gold. You see the entire line’s status at a glance. Operators look at them constantly. Even office staff often stop to check them. It really helped with system adoption.”

3. ERP integration with IFS

A major step in the project was the integration with the IFS ERP system. Previously, operators had to manually record production output. Now, every 40 kg produced is automatically logged in the ERP system. When an order is completed, IFS notifies Ignition, which then prepares the next order.

4. Quality registration

All quality checks – once recorded on paper and later manually entered into Excel – are now entered directly into the system. Every order is now fully traceable, from production data to quality results.

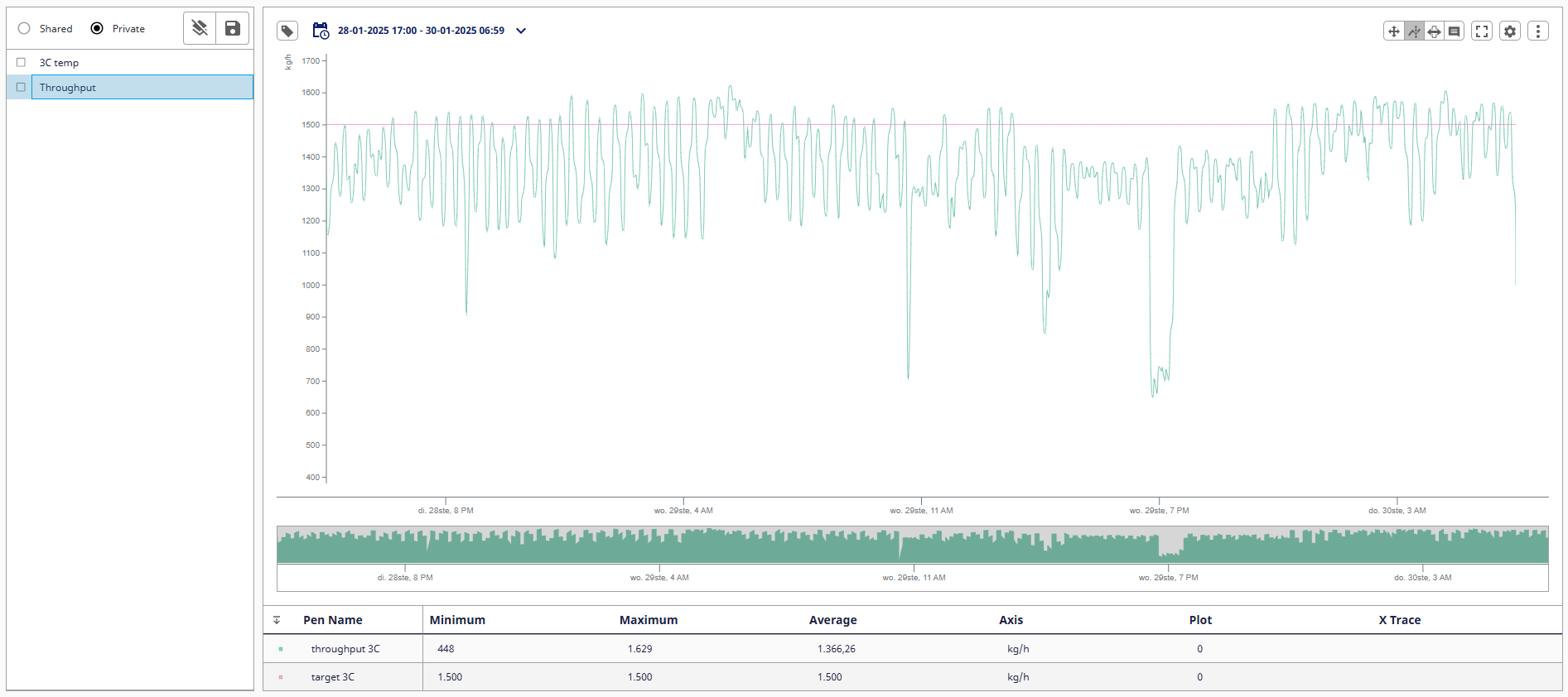

5. Historian

Perhaps the most powerful component is the historian, which stores and visualizes all data. Rob and his team use it daily. “Before this, it could take us a week to analyze a malfunction. Now, we’re on the right track in 10 minutes. And we solve problems in ways that prevent them from happening again. That alone paid for the system within a year.”

What has it delivered?

The benefits of the new solution are crystal clear, according to Rob:

- Reliable data: No more guesswork – just hard facts.

- Faster analysis: Issues are resolved quicker and more effectively.

- Less administration: Operators no longer enter data manually.

- Improved monitoring: Operators intervene earlier and understand the process better.

- Automated reporting: Every morning at 7:00, a detailed report is sent to management, with zero effort required.

- High engagement: Thanks to the large screens, everyone – from operators to clients – understands what’s happening in the factory.

- Rapid ROI: The time savings from improved troubleshooting alone paid for the system within a year.

“We used to work with pen and paper. Now we have a system that supports us every day, gives us insight, and continually improves our processes. It works, it’s scalable, and thanks to the training we received from AT-Automation, we can even expand it ourselves. The best part? Our operators actually use it. And that might be the biggest compliment of all. I’m incredibly proud of what we’ve built here together.”

Rob Keunen, LDPE Recycling

Ready to master your growth?

At AT-Automation, we are committed to accelerating your growth and helping you reach new heights in efficiency through our advanced automation solutions. We firmly believe in sharing knowledge and empowering individuals to become masters in industrial automation. Would you like free, no-obligation advice on how our solutions can help your business grow?

Leave your contact details below – we’ll be happy to connect.